PharmaLab™ is the fully automated platform that manages the entire quality control process for the pharmaceutical industry, from plate handling to incubation, from image analysis to reporting.

PharmaLab™ AI-based image analysis system detects growth instantly. Its compatibility with any LIMS ensures automatic and digital traceability from sample incoming to final results. Automatic result storage guarantees data integrity for audits. All these features streamline your environmental control and save time from non-added value tasks.

With over 1.300 automated systems installed worldwide in the clinical, food, and forensic sectors, we are now expanding into the pharmaceutical industry. The highlight of our technology is image analysis, powered by an AI-driven neural network system, which processes high-quality images to deliver precise results.

Designed for pharmaceutical quality control

Delegating your routine to PharmaLab™ lowers the risk of human error and reduces your staff workload. This enhances the quality of your data in a lab running 24/7.

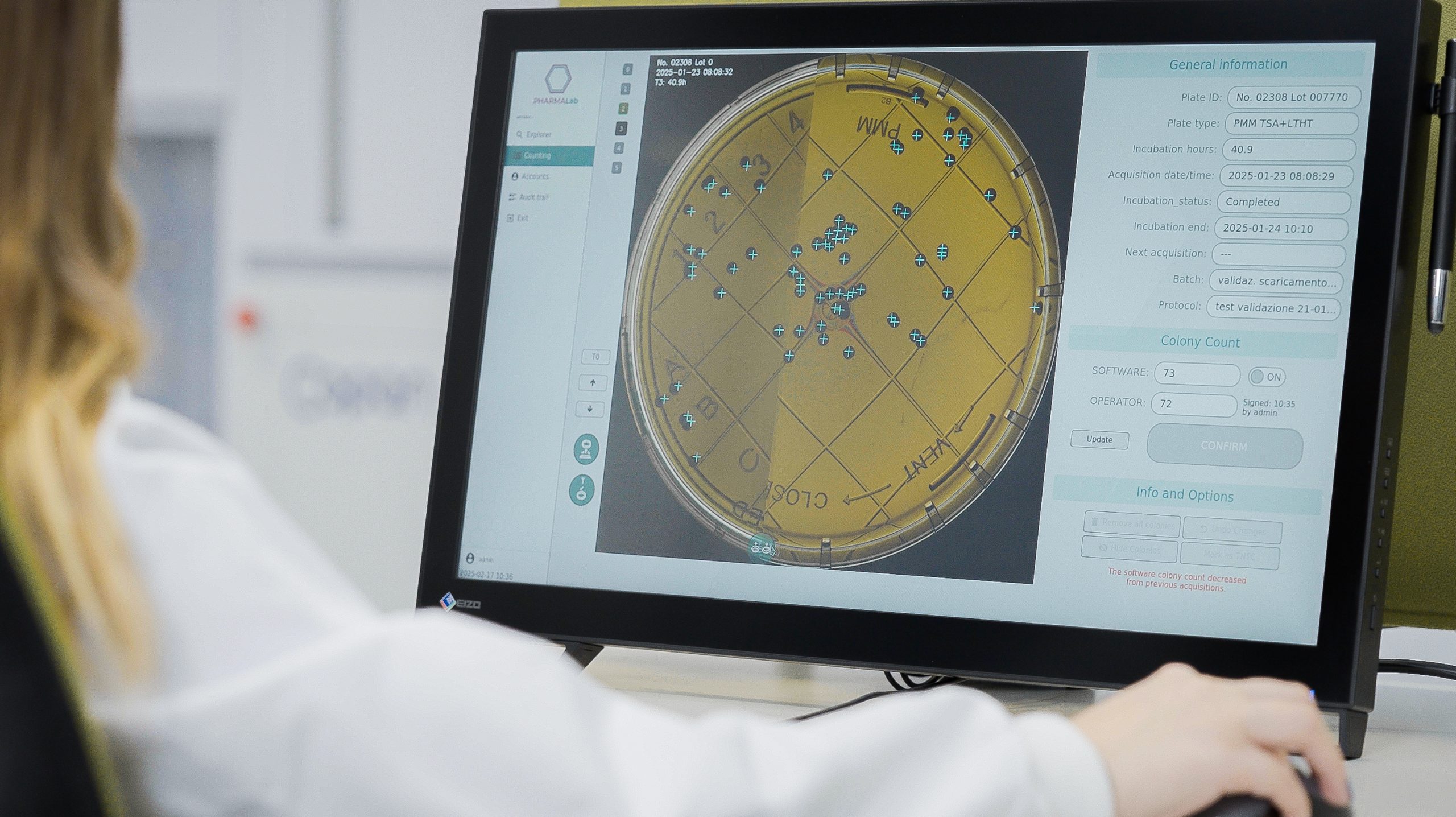

Compliant with 21 CFR pt. 11, PharmaLab™ tracks every action taken, eliminating any opportunity for manipulation or interference. Its adaptable software connects with any LIMS provider upon user request, ensuring complete data traceability, seamless integration with the laboratory network, and worry-free inspections and audits.

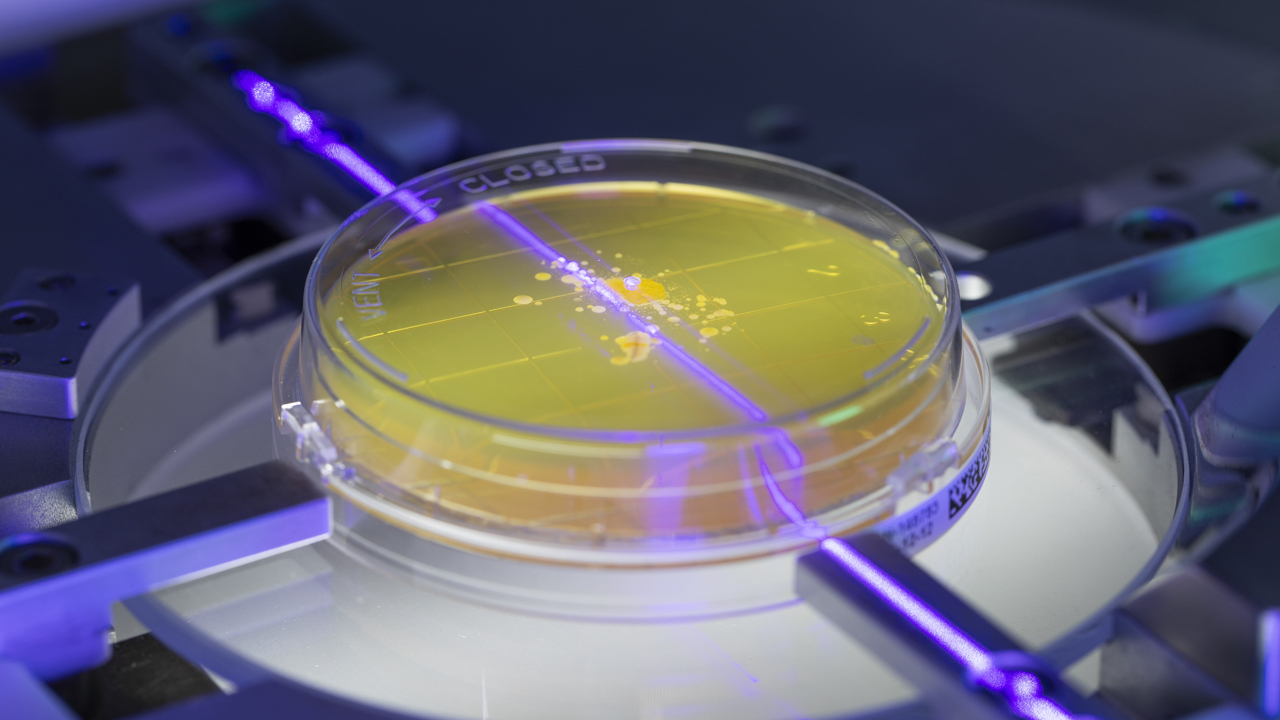

The image analysis system can detect colonies earlier, significantly reducing reaction time.

Enjoy the automatic colony count and detection. Turn, pinch, flip, reverse, and light up pictures. Scroll backward and forward through growth phases. PharmaLab™ accurate software brings your lab unparalleled efficiency and sensitivity.

PharmaLab™ is compatible with your brand and type of plates. Based on your requirements, Copan specialists can quickly size the equipment to cover the laboratory workload.

Plates are placed into the dedicated carousel for easy loading

Plates are scanned immediately to obtain protocol information from the LIMS and ensure timely tracking.

The camera acquires plate images at time zero to enable differential analysis.

Colonies are automatically counted and displayed on the integrated software interface

Plates are sent to the incubator after each acquisition and recalled for intermediate pictures

Plates are stacked in a dedicated output carousel for further analysis or discarded if no growth is detected.

Write us to satisfy your curiosity, get information or start a great collaboration!

Use our search tool and be surprised by how easy it is to get right to the point.